Fatigue

Life Correlations

Coffin-Manson and Morrow's Fatigue

Laws

Hysteresis loops provide useful information for engineering

evaluations of solder joint reliability. For example, the

width of the loop gives an estimate of the inelastic strain

range that solder joints experience. The inelastic strain

range is used in Coffin-Manson type of fatigue laws.

Another, more general approach consists in using the hysteresis

loop area which is a measure of the amount of cyclic strain

energy density that is imparted to solder joints. Strain energy

density is used in Morrow's type of fatigue laws (Morrow,

1964, Ohtani et al., 1985) where cycles to failure are given

as a function of the cyclic inelastic strain energy density,

Win: Win: |

|

(25) |

| special definitions: |

| |

C |

material constant |

|

| |

n |

exponent, has been found in the range 0.7 to 1.6

for several

engineering metals, including soft solders |

|

|

Sn-Pb Solder Joint Reliability

Models

Several engineering models have been developed to predict

solder joint reliability based on Coffin-Manson (e.g. Norris-Landzberg,

1969; IPC-SM785) and Morrow's fatigue laws (e.g. Darveaux

et al., 1995; Clech, 1993, 1996). For example, the Darveaux

model uses inelastic strain energy obtained from finite element

analysis to correlate fatigue lives from over 100 experiments.

The Solder Reliability Solutions (SRS) model (Clech, 1996)

derives strain energy densities from simplified, one-dimensional

structural models and correlates failure data from over 60

experiments. |

|

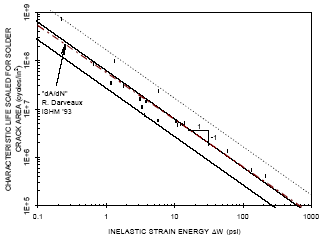

Figure

5: SRS correlation of accelerated test data. |

|

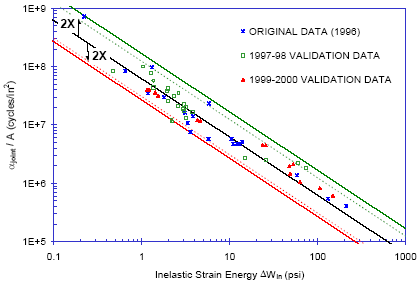

Figure 6: Fit of validation data to initial

correlation of solder joint fatigue lives.

Figure 5 shows the SRS correlation of fatigue

life data from nineteen accelerated tests (Clech, 1996).

The correlation gives joint characteristic lives scaled

for the solder crack area, ajoint / A, versus cyclic inelastic

strain energy. The life prediction model based on the best-fit

line going through the data (centerline of correlation band

in Figure 5) was frozen based on 19 experiments. Figure

6 is similar to Figure 5 with 35 data points added in for

model validation (Clech, 2000). Lessons learned from developing

this type of engineering life prediction model, as well

as from Darveaux’s model, are:

-

Given the semi-analytical, semi-empirical

nature of the models, it is important that they be validated

over time when data becomes available for new types of

packages or assemblies.

-

For these models to be more reliable,

the empirical correlation of life data should hold over

several orders of magnitude on both axis, i.e., for inelastic

strain energy (or another damage parameter) and the crack

propagation rate or other life parameter. Note, for example,

that the data plotted in Figures 5 & 6 extends over

three orders of magnitude on the horizontal and vertical

axis.

|

|

SAC vs. SnPb

Fatigue Data

|

|

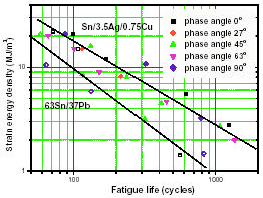

Figure 7: SnPb and SAC

fatigue life vs. strain energy correlations (after Park

et al., 2002).

Figure 7 shows correlations of isothermal, mechanical fatigue

lives versus inelastic strain energy for eutectic SnPb and

Sn3.5Ag0.75Cu lap-joint specimens tested at 25°C (data

after Park et al., 2002). This suggests that SAC thermo-mechanical

failure data may correlate to strain energy as in the case

of neareutectic SnPb electronic assemblies. In Figure 7,

the slope of the best-fit line through the 63Sn/37Pb data

is close to –1, similar to the corresponding slopes

in the Darveaux and SRS models for near-eutectic SnPb assemblies.

However, the slope of the line through the Sn3.5Ag0.75Cu

data points in Figure 7 appears to be slightly less than

–1 (i.e. the exponent n in equation (25) would be

greater than 1). This suggests that existing methodologies

for predicting SnPb solder joint lives may apply to SAC

electronic assemblies. However, both the intercept and the

slope of life correlations such as shown in Figures 5 and

6 would have to be adjusted using extensive empirical data.

|

|